Powder Bed

Fusion Technology

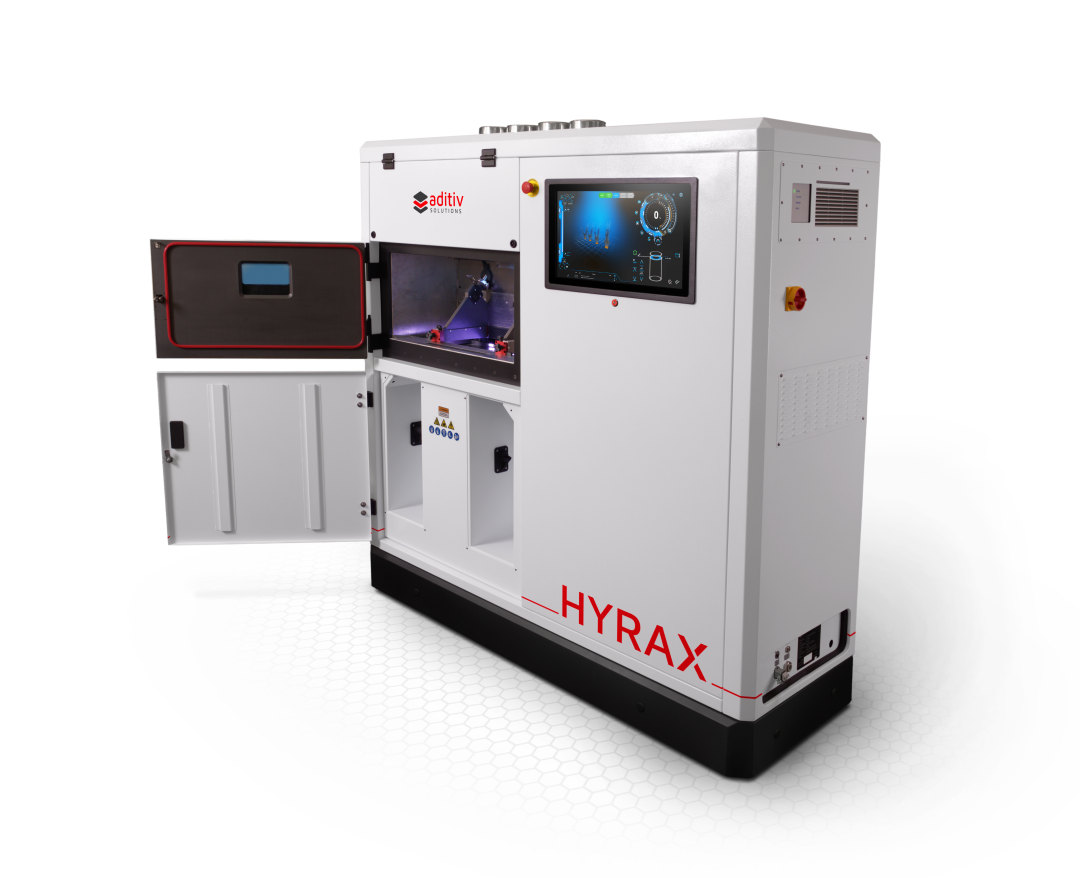

HYRAX: Our flagship technology for cost-efficient metal printing without compromise.

Aditiv Solutions specialises in designing and manufacturing Metal 3D Printers, also recognized as Additive Manufacturing equipment. Our cutting-edge technology employs powder bed fusion to produce intricate metal parts. We are proud to boast that our innovative 3D printers are among the most cost-efficient laser-based metal printers on the planet.

In addition to our cutting-edge machines, we offer comprehensive turnkey solutions to cover every step of your 3D printing process, from powder handling to post-processing.

Plus, we provide professional 3D printing services for both metal and polymer parts.

Explore what we do and discover new possibilities…

Our Machines

Introducing the HYRAX, exclusively designed and manufactured by Aditiv Solutions, our flagship metal 3D printer revolutionises the industry with its cost-efficient and high-quality printing capabilities. Boasting superior German optical systems and a powerful 400W laser, the HYRAX excels at crafting small to medium-sized parts.

Versatility is its strength, with the ability to print in materials like Stainless Steel, Tool Steel, Nickel Alloys, Titanium, Aluminium, and Cobalt-Chrome.

It is simple to operate and install and effortlessly fits through a standard door, requiring only single-phase power and an inert gas supply.

Explore the impressive features of our state-of-the-art machine and experience its user-friendly multi-touch interface

Technology

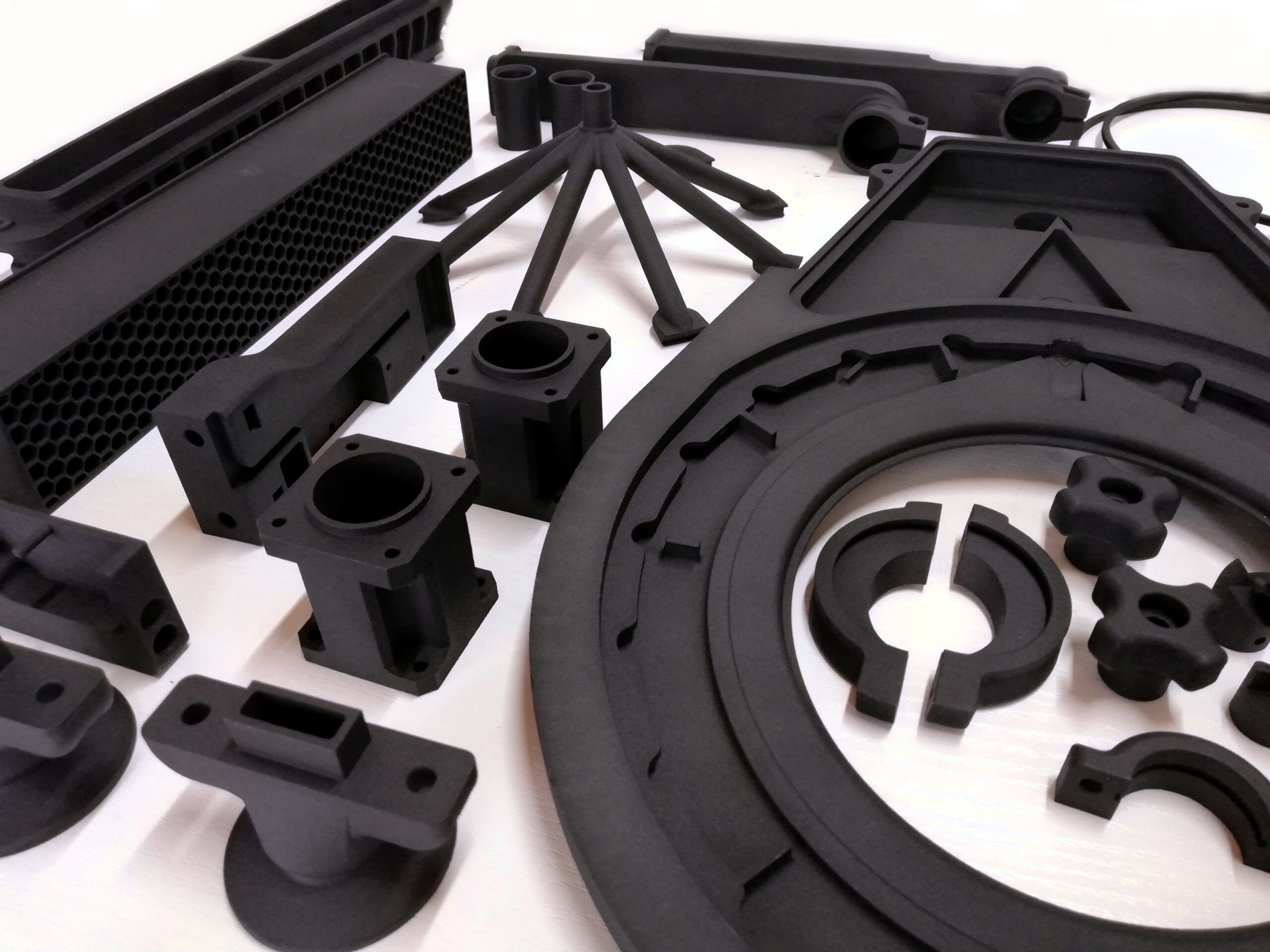

Harnessing the power of laser technology, our powder bed fusion machines transform metal powder directly into intricate, strong and impeccably precise parts.

Why our machines?

Value

The HYRAX is one of the most cost-efficient production systems available, enabling more applications and industries to utilise metal 3D printing.

Open Architecture

Unlike others, we do not limit our customers. We allow our customers to use any printable metal and process parameters they choose.

Process Reliability

We utilise the highest quality German optical systems in our machines to ensure build consistency and accuracy for every part.

Operating Environment

The HYRAX has a small footprint, is fast and easy to deploy, requires minimal support equipment and runs from single-phase power.

Get To Know The HYRAX

Get To Know The HYRAX

Need Some 3D Printed Parts?

Since everyone doesn’t want their own printer (yes, really…), we also offer 3D printing services to cover both metal and plastic parts. Our expertise lies in the creation of industrial-grade 3D printed parts in common engineering materials.

To get an instant quote and place an online order, simply upload your files here. Alternatively, if you prefer a more traditional approach, send us your files (3dprinting@aditiv.co.za), and our dedicated team will be in touch promptly.

Metal 3D Printing

Metal 3D printing is a great solution to produce intricate metal parts directly from powder. Parts have excellent mechanical properties and can be produced with a high resolution.

Plastic 3D Printing

Nylon 12 is a versatile material used to print durable and intricate parts with good dimensional accuracy. This is our workhorse and is perfect for production runs or prototypes.

Plastic 3D Printing (Colour)

Require some colour in your life? This process produces Nylon 12 parts in full colour. The technology is commonly used for prototypes where this added visual appearance will seal the deal.

Turnkey Solutions

We recognize that each of our customers has unique requirements. Our approach involves working closely with you to ensure that the most fitting solution is achieved.

Feel free to reach out and let us know what you need to make your business work.

RAPID + TCT

Mark your calendars for 25 – 27 June 2024, and join us at the Los Angeles Convention Center.

We’ll be waiting for you at booth 1067, ready to showcase our latest innovations and share our passion for additive manufacturing.

Our Awesome Partners

Contact Us Today

info@aditiv.co.za

(General Enquiry)

3dprinting@aditiv.co.za

(3D Printing Service)